Wire mesh screen in commercial applications

Wire mesh screens are increasingly being used in various commercial applications to provide a wide range of benefits. These screens offer many advantages, both aesthetically and functionally, from providing extra security and privacy to allowing air circulation and light transmission. They are also designed to be durable and weather resistant with minimal maintenance required, making them a practical choice for many businesses. In addition, wire mesh screens come in a variety of colors, styles, and sizes that can be tailored to fit any space or setting.

Wire Mesh screen use

Wire mesh screen is a versatile material that has numerous commercial applications. One of the most common uses of wire mesh is in screens for filtering and separating materials during production processes. Wire mesh screens can be made from a variety of materials, including stainless steel, brass, and copper. The size and shape of the wires used to make the mesh can also vary depending on the intended application.

Wire mesh screens are commonly used in industries such as food processing, mining, construction, and agriculture. In food processing plants, wire mesh screens are used to filter out impurities or separate different ingredients during production. In mining operations, wire mesh screens are used to sift through soil or aggregate for valuable minerals or metals.

Wire mesh screens can also be utilized in construction projects as reinforcing material for concrete structures such as walls or bridges. The use of wire meshes in construction provides additional strength while allowing for flexibility in design options.

In summary, wire mesh screen is an essential material with numerous commercial applications due to its versatility and durability. From food processing plants to construction sites – it plays a vital role in many different industries by providing strength and stability while offering unique design possibilities.

Applications: Industrial & Commercial

Wire mesh screens are commonly used in commercial applications where the need for ventilation, separation, or filtration arises. In industries such as food processing, wire mesh screens are used to keep insects and other unwanted particles out while allowing a flow of fresh air into the building. Moreover, wire mesh screens are also popularly used as fencing material in commercial areas to provide security without obstructing visibility.

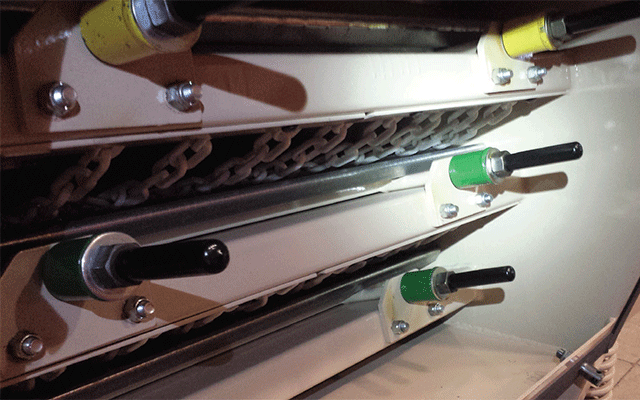

Wire mesh screen can also be found in industrial applications such as mining and construction. This is because they offer superior strength, durability and resistance against harsh environmental conditions. Additionally, wire mesh screens can also be customized to suit specific needs such as size or thickness, making them ideal for use as sieves or filters in various industrial processes.

Overall, wire mesh screens possess versatile qualities that make them an excellent choice for both industrial and commercial applications. Their functionality extends beyond basic screening needs providing cost-effective solutions for different industries requirements with their customizable features.

Varieties of Wire Mesh Materials

Wire mesh screens are used in a variety of commercial applications, including filtration systems, fencing, and construction projects. The type of wire mesh screen material chosen depends on the specific application requirements. Stainless steel wire mesh is one of the most common materials used for industrial filtration and separation processes due to its durability and resistance to corrosion. It is also easy to clean and maintain, making it a popular choice for food processing plants.

Another popular wire mesh material is aluminum. This lightweight metal offers excellent strength-to-weight ratios, making it an ideal choice for architectural applications such as facade cladding or sunscreens. Brass wire mesh is often used in decorative applications due to its attractive golden color that can add aesthetic value while still providing functionality as a screen or filter.

In addition to these common materials, there are many other varieties available, depending on the specific needs of each project. Copper wire mesh provides good electrical conductivity and thermal stability, while titanium wire mesh offers high strength-to-weight ratios with exceptional corrosion resistance properties. By understanding the different types of wire mesh materials available, businesses can choose the best solution for their unique commercial application needs.